TI’s PLDs Help Engineers Leap From Concept to Prototype in a Snap

The new family of programmable logic devices highly integrates features to reduce board space by up to 94%.

Today, Texas Instruments (TI) introduced a new family of programmable logic devices (PLDs) to simplify logic integration and accelerate time to market for designers.

Consumers demand compact electronic devices that integrate multiple functions. To meet these requirements, the modern engineer must balance performance, power consumption, and space constraints while managing rising system costs.

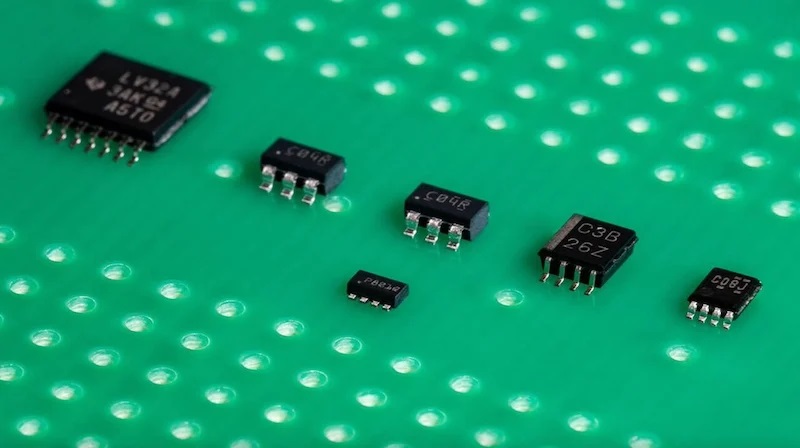

TI’s new programmable logic portfolio.

In the world of digital logic, traditional discrete logic implementations can be cumbersome, adding to design complexity and limiting flexibility when changes are required. Programmable logic devices, like TI's new portfolio (TPLD801, TPLD1201, and TPLD1202), are a useful solution to reduce board space, consolidate functions, and lower power usage.

TI Introduces New PLD Family

TI's new range of PLDs integrates up to 40 logic and analog functions, providing significant space savings—up to 94% compared to discrete logic solutions. By incorporating sequential and combinational logic in compact packages, the new PLDs can also reduce system costs. When paired with TI's no-code design tool, InterConnect Studio, the PLDs reduce development time by enabling drag-and-drop circuit creation and simulation without programming expertise.

The PLD series also reduces system power consumption while extending the operational life of battery-powered devices. With quiescent currents under 1 µA and active power consumption reduced by 50% compared to competing PLDs, the devices are said to be well-suited for energy-conscious applications such as electric vehicles, battery-powered tools, and portable consumer products. The devices are available in compact packages as small as 2.56 mm², with leaded and non-leaded options, including automotive-grade models that meet AEC Q-100 standards for temperature and reliability.

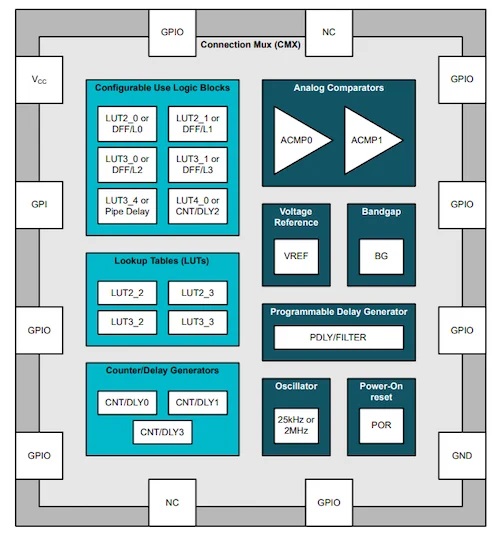

TPLD1201 block diagram.

As an example of the new family, the TPLD1201 (datasheet linked) is housed in a 12-pin QFN or VSSOP package and operates across a temperature range of -40°C to 125°C. It accepts a supply voltage range from 1.71 V to 5.5 V and integrates a combination of digital and analog features, including eight GPIO pins, configurable lookup tables, 8-bit shift registers, counters, and pattern generators. It also integrates an analog comparator with selectable voltage references and hysteresis for mixed-signal designs, allowing system designers to consolidate multiple functions into a single IC.

PLDs Address the Challenges of Feature-Rich Designs

In modern electronics design, balancing performance, size, and power efficiency has become increasingly challenging. As systems grow more complex, traditional discrete logic designs often require multiple ICs to handle various functions, such as timing, resets, and voltage monitoring. Due to the number of individual components, these designs consume significant board space, increase power consumption, and drive up manufacturing costs. For engineers working in space-constrained environments like automotive, industrial automation, and portable electronics, these limitations can complicate an efficient design.

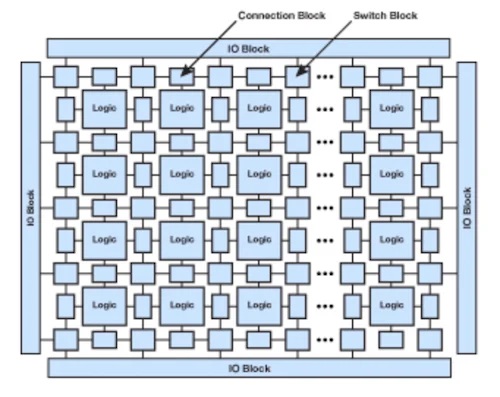

PLDs consist of interconnected logic blocks.

PLDs address many of these challenges by integrating multiple logic and analog functions into a single, compact IC. Unlike discrete logic, PLDs allow designers to reduce their component count and shrink their PCB footprints by as much as 94% in TI’s case. The results are lowered costs, decreased BoM, and even lower power consumption as a result of more cohesive system operation. PLDs also eliminate the need for hardware modifications when design changes are required. Instead of altering the PCB layout or replacing components, engineers can simply reprogram the PLD to update the system.

Compared to more complex solutions like FPGAs and ASICs, PLDs offer a simplified path to integration. While FPGAs are known for their extensive configurability, they often require advanced software programming and incur higher costs due to their larger gate counts and power consumption. ASICs, while efficient for high-volume applications, lack the flexibility to adapt to changing requirements post-production. In contrast, PLDs provide a balance of flexibility and ease of use, with reprogrammable functionality that does not require specialized coding knowledge.

High Integration, Low Power

As electronics continue to evolve, the integration of logic and analog functions into smaller, more efficient systems will remain essential. TI’s latest offering is a clear indicator of this trend, allowing engineers to address the growing complexity of their systems without sacrificing power efficiency or board space. Production quantities of TI’s new PLDs are currently available on the company’s website.

.jpg)

.jpg)