DGT Technology (HK) Co., Limited is certified ISO 9001:2015. Our commitment to quality shown through ISO certification is to demonstrate to our customers that top management is committed to providing customers with authorized genuine components with the least risk of counterfeit. At DGT Technology (HK) Co., Limited we can provide full traceability on the commercial components sold. From sales to shipping DGT Technology (HK) Co., Limited is committed to meeting your requirements for the right product, on time.

Our mission is to be the source most preferred by engineers and buyers to design, prototype, test and manufacture electronics. See our Quality Policy, Quality Manual and Certificate. DGT Technology (HK) Co., Limited is committed to gratifying and astonishing customers with our customer service excellence, order accuracy and on-time delivery. This is accomplished through our commitment to continual improvement of our processes, services, products and our people.

We are constantly working towards improvement of our procedures and processes, thus providing our customers with products that meet or exceed all requirements, are delivered on-time and function reliably throughout their useful life.

Quality Assurance Testing

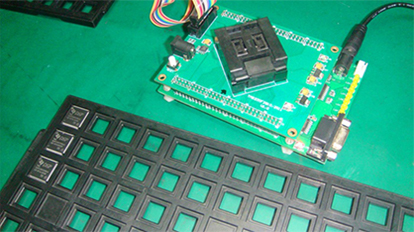

DGT Technology (HK) Co., Limited has partnered with White Horse Laboratories and CECC Laboratories to support global procurement and Supply Chain Management commitments to our clients. DGT Technology (HK) Co., Limited established testing, inspection, and packaging business unit in response to the growing proliferation of substandard and counterfeit electronics components.

In a challenging environment “Quality is a must”. DGT Technology (HK) Co., Limited can provide test reports and product quality verification on almost all components prior to dispatch when required. DGT Technology (HK) Co., Limited testing services include a secure network of certified third-party laboratories/facilities supporting our comprehensive distribution network. This extensive network provides expert product testing for incoming products to ensure customers risk-free engagements time after time. Electronic component quality testing is done to identify any substandard material and to verify that all manufacturers’ specifications are met. Product samples are also randomly selected and periodically tested to ensure product consistency and to document spot quality control.

We can offer

In the ever changing electronics industry there is an increased requirement for electronics component test services and component verificaton.Eparts offer electronics component testing services to aid in fake component detection.Most parts from us are test by functionally.We try our best to avoid any fake,defective go to our customer and into market.

Level 1 Visual Inspection

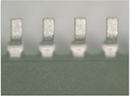

Genuine

Before wiping

After wiping

As shown above: true screen printing is still clear after wiping

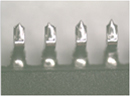

Fake

Before wiping

After wiping

As shown above: fake screen printing is blurred after wiping

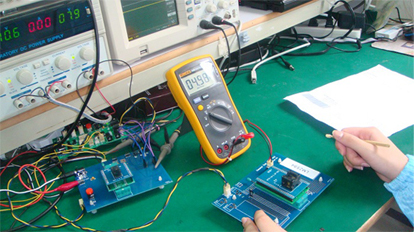

Level 2 Electrical Testing

Electrical testing is involving the testing of each contact on a component to ensure that the components are satisfied by datasheet.This is very strong tool to tell us if the component is defevtive or not.

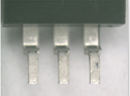

Level 3 Solderability Testing

Metal oxidizes it is easy happen. We call it “rust”. On solder, it is referred to as oxidation . Other contaminants such as oil and dust can cause the solder to not make a good connection between the component terminal and the printed circuit board (PCB). It can determine if the devices will be able to be soldered in customer application.It is fast way,inexpensive and invaluable.

Genuine

Before soldering

Success of soldering

As picture shown above:Joint of soldering is smooth and connect with the pins closely

Fake

Before soldering

Soldering failure

As picture shown above:Solder failure joint of soldering is not smooth and easy to fall off