Weebit’s ReRAM Is Now AEC-Q100 Qualified. What Does That Mean?

Announced at Embedded World 2025, Weebit Nano's ReRAM module has met a critical benchmark for ICs used in vehicles.

Weebit Nano has achieved a significant milestone by fully qualifying its resistive random-access memory (ReRAM) module to the AEC-Q100 standard for automotive applications. This announcement, made at Embedded World 2025, highlights the reliability and robustness of Weebit’s non-volatile memory (NVM) technology.

Eran Briman (left), VP of marketing and business development at Weebit Nano, talked with All About Circuits' Jeff Child about the significance of the AEC-Q100 qualification at Embedded World 2025.

AEC-Q100 qualification is a crucial benchmark for automotive-grade electronics, ensuring that components can withstand extreme conditions. By securing this certification, Weebit Nano positions its ReRAM as a strong alternative to traditional Flash memory in high-reliability environments, from vehicles to industrial applications.

Why Does AEC-Q100 Matter?

AEC-Q100 is an industry-standard developed by the Automotive Electronics Council (AEC) to define stress testing requirements for integrated circuits (ICs) used in vehicles. Originally established by Chrysler, Ford, and GM, the standard has evolved to accommodate advancements in semiconductor technology. It serves as a vital assurance of component reliability, particularly in mission-critical automotive applications where failures can lead to safety hazards and costly recalls.

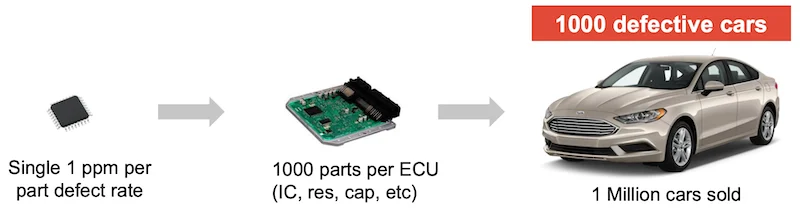

Example of why AEC-Q100 matters. Image used courtesy of Monolithic Power

The qualification process involves rigorous testing, including high-temperature operating life (HTOL), program/erase endurance, and data retention tests. Components are categorized into four temperature grades, with Weebit's ReRAM qualifying for Grade 0 (-40°C to 150°C), the highest level of endurance. Over the years, AEC-Q100 has seen revisions to address the increasing complexity of automotive electronics, with newer requirements focusing on fault simulations, electrostatic discharge (ESD) protection, and enhanced durability standards.

Weebit’s ReRAM

Weebit Nano’s ReRAM module underwent comprehensive testing to meet AEC-Q100’s stringent requirements. The qualification process demonstrated its ability to maintain stability at 150°C for up to 100,000 endurance cycles—performance comparable to or exceeding traditional Flash memory solutions. This certification validates ReRAM’s potential to replace NOR and NAND Flash in applications that demand high endurance and resilience under extreme conditions.

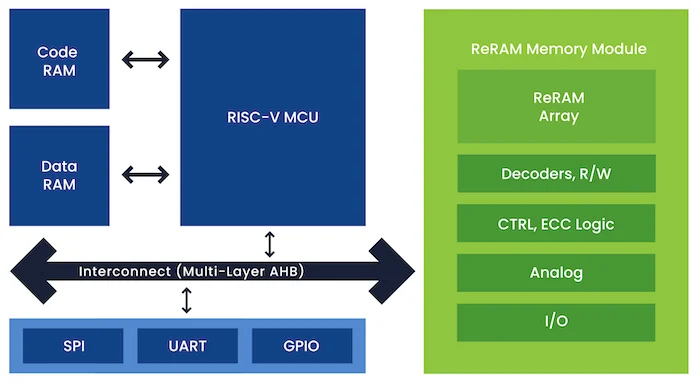

Embedded ReRAM demo chip. Image used courtesy of Weebit Nano

Beyond endurance, ReRAM’s low power consumption, faster read/write speeds, and simplified architecture make it an attractive choice for embedded systems. Unlike conventional Flash memory, which requires high-voltage operation for write cycles, ReRAM operates at lower voltages, reducing overall power consumption. This efficiency is particularly beneficial for modern electric and hybrid vehicles, where energy efficiency is a key design consideration.

ReRAM in Automotive, Industrial, and IoT

While the primary impact of AEC-Q100 qualification is on automotive applications, its significance extends far beyond. Industrial and IoT applications, such as downhole tools, smart infrastructure, and high-temperature manufacturing environments, also require memory solutions with exceptional endurance and thermal stability. This qualification reassures designers in various industries that ReRAM is a robust and reliable memory option.

Market forecasts suggest that the automotive semiconductor industry will grow from $52 billion in 2023 to $97 billion by 2029, driven by vehicle electrification and advanced driver-assistance systems (ADAS). The increasing reliance on AI, machine learning, and edge computing within automotive applications also creates demand for memory technologies that can support rapid data processing with minimal power consumption. With its newly qualified ReRAM, Weebit Nano is well-positioned to address these evolving market needs.

As automotive and industrial applications continue to push the boundaries of electronics performance and reliability, ReRAM offers a compelling alternative to traditional Flash memory. Its endurance, power efficiency, and seamless integration potential make it a promising option for designers looking to future-proof their systems.