What Will Sustainable Semiconductor Manufacturing Look Like by 2035?

In a recent report, IDTechEx defined the who, what, and when of sustainable IC and PCB manufacturing.

IDTechEx has compiled a report highlighting the challenges and opportunities of the next decade’s sustainable semiconductor manufacturing processes. This report highlights the key manufacturers, impacted markets, sustainability metrics, and growth forecasts of these markets.

Cutting back on electronic waste ("e-waste") is a common sustainability goal for many semiconductor companies. Image (modified) used under Adobe Stock license.

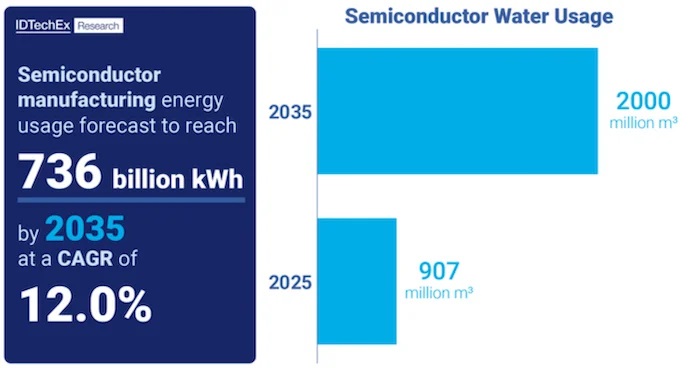

The report projects that energy usage is growing by 12% CAGR and that water usage is increasing by 8% CAGR.

Sustainability is a high priority in many corporate structures and an important goal for investors and the general public. As part of these sustainability goals, semiconductor manufacturers are looking for ways to make the entire development process more environmentally friendly.

Semiconductor Supply Chain and Environmental Hazards

The manufacturing of integrated circuits (ICs) and printed circuit boards (PCBs) causes several key environmental impacts, such as toxic chemicals, high water and energy usage, and electronic waste.

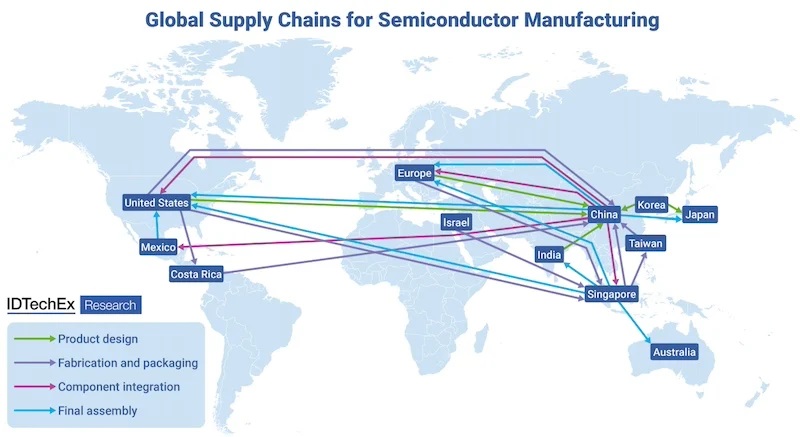

These challenges span the globe across design, assembly, packaging, and integration teams. A processor chip designed in the United States may be sent to China (within the scope of ITAR restrictions), integrated again in the United States, and sent to Costa Rica for sorting and packaging before being sent to Spain for its final use. Therefore, sustainability challenges must be solved at the global level, with many key players optimizing their resources and jointly promoting green initiatives.

A snapshot view of global supply chains. Image used courtesy of IDTechEx

Some manufacturers are now using recyclable and biodegradable materials to replace FR4 for PCBs. Future regulatory ramifications may drive some of this innovation. For example, the European Union is pushing for digital passports (DPP), and the Ecodesign for Sustainable Products Regulation (ESPR) is also driving for more sustainable alternatives.

Water and Energy Usage in Semiconductor Fabrication

In the United States, many of the major semiconductor manufacturing facilities are located in arid climates, where water is a vital commodity. Intel, for example, has facilities in Rio Rancho, New Mexico, and Chandler, Arizona. Amkor also has a facility in Arizona. Texas Instruments has built a facility in Utah. In all of these cases, local and state government incentives, cost-effective land, and other factors have driven these companies to build in the West.

One downside to these locations is that water is scarce, and semiconductor fabrication uses a lot of it—approximately 500 billion liters of water annually. Water is purified and used to wash away chemical etchants, dilute solvents, and act as a process fluid for cooling plates.

Energy and water usage growth over the next decade. Image used courtesy of IDTechEx

IDTechEx’s report discusses some of the ways in which semiconductor manufacturing plants can save both water and energy. Intel, Microchip, TSMC, and several other fabrication facilities are testing ways to combine processing steps and remove unnecessary ones. This not only saves precious water resources in arid lands, but it can also help improve the facility’s bottom line without sacrificing throughput or quality.

The Future of Sustainability in Semiconductors

As semiconductor manufacturers seek ways to cut their operating expenses and meet their environmental, social, and governance (ESG) goals, sustainability will continue to be an important issue. Understanding how companies are currently using resources will be essential in determining investments.

To learn more about sustainability efforts in the semiconductor industry, you can refer to IDTechEx's latest report: Sustainable Electronics and Semiconductor Manufacturing 2025-2035: Players, Markets, Forecasts.

.jpg)